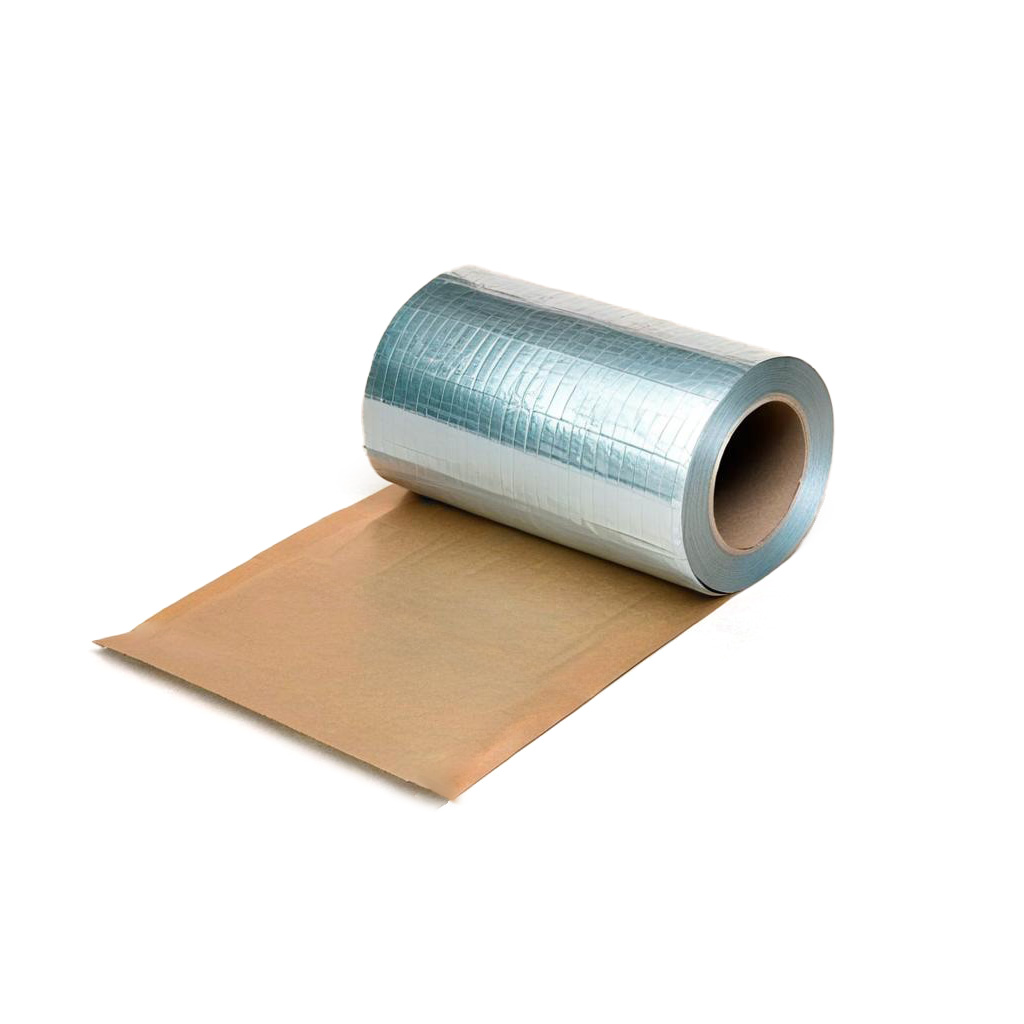

Heat Sealing Aluminum Foil Facing – High Performance and Eco-Friendly Insulation

Overview

Our Heat Sealing Aluminum Foil Facing consists of aluminum foil, scrims, and virgin Kraft paper, with a heat-activated polyethylene (PE) coating on the Kraft side. This product is designed to provide high tensile strength, corrosion resistance, and an environmentally friendly insulation solution by eliminating the need for extra adhesives. Its wide application range makes it suitable for use in glass wool, rock wool, and mineral wool insulation systems.

Key Features

- Heat-activated PE coating: No need for additional adhesive, making installation easier and more eco-friendly.

- High tensile strength: Ensures durability and longevity in various insulation applications.

- Corrosion resistance: Excellent protection against environmental factors.

- Wide application range: Ideal for high-quality in-line lamination of glass wool, rock wool, and mineral wool insulation.

Upgrade your insulation with our heat-activated aluminum foil facing, perfect for lamination without the need for additional adhesives. Contact us today for a custom quote!

Applications

Heat Sealing Aluminum Foil Facing is a versatile and eco-friendly solution for various insulation needs:

- Lamination for Wool Insulation

This material is perfect for high-quality, in-line lamination of glass wool, rock wool, and mineral wool insulation. With no need for extra adhesives, it simplifies the lamination process while enhancing the insulation's durability. - Corrosion-Resistant Insulation

Thanks to its excellent corrosion resistance, this material provides long-lasting protection for insulation systems, ensuring they remain effective and protected from environmental elements. - Environmentally Friendly Installation

The heat-activated polyethylene coating on the Kraft side eliminates the need for additional adhesives, making the installation process more environmentally friendly by reducing the use of chemicals.

Benefits of Heat Sealing Aluminum Foil Facing

- Eco-friendly: No need for additional adhesives, reducing the environmental impact.

- Durable: High tensile strength and corrosion resistance ensure long-lasting performance.

- Wide application range: Suitable for a variety of insulation types including glass wool, rock wool, and mineral wool.

- Customizable: Available in various thicknesses, widths, and lengths to meet your needs.

Product Specifications

| Item Code | Description |

| AHSF-75025 | Aluminum foil: 7µ + PE + Diamond Scrim: 8*12/100mm + Natural Paper: 50gsm + PE: 25µ |

| AHSF-75025AR | Aluminum foil: 7µ + FR Glue + Natural Paper: 50gsm + Diamond Scrim: 8*12/100mm + PE: 25µ |

| AHSF-75025BR | Aluminum foil: 7µ + FR Glue + Natural Paper: 50gsm + Scrim: 12.5*12.5mm + PE: 25µ |

| AHSF-75025CR | Aluminum foil: 7µ + FR Glue + Natural Paper: 50gsm + Scrim: 12.5*6.25mm + PE: 25µ |

| AHSF-1825 | Aluminum foil: 18µ + Square Scrim: 5*5mm + PE: 25µ |

| AHSF-1550 | Aluminum foil: 15µ + Square Scrim: 3*3mm + PE: 50µ |

| AHSF-750 | Aluminum foil: 7µ + PET + Square Scrim: 3*3mm + PE: 50µ |

| AHSF-1225 | MPET: 12µ + PE: 25µ |

| AHSF-730 | Aluminum foil: 7µ + PE: 30µ |

| AHSF-745R | Aluminum foil: 7µ + FR glue + Fiberglass cloth: 80gsm + PE: 45gsm |

| AHSF-720 | Aluminum foil: 7µ + PET: 12µ + PE: 20gsm |

| AHSF-7 | Aluminum foil: 7µ + Binder + HDPE Woven + PE Film |

Customization Options

- Foil, MPET, and PE coating thickness: Can be adjusted to meet specific project requirements.

- Widths available: 1.0m, 1.2m, 1.5m.

- Lengths available: 60m, 200m, 300m, 1000m.

- Custom sizes: Products can be tailored to your specifications.

Looking for an efficient, eco-friendly insulation solution? Get in touch with us today for a custom quote and let us help you find the perfect Heat Sealing Aluminum Foil Facing for your project.

Frequently Asked Questions

- 1. What is Heat Sealing Aluminum Foil Facing used for?

It is mainly used for in-line lamination of glass wool, rock wool, and mineral wool insulation. The heat-activated polyethylene coating eliminates the need for additional adhesives. - 2. Is this material environmentally friendly?

Yes, it does not require extra adhesives, making the installation process more eco-friendly by reducing the use of chemicals. - 3. Can the thickness of the foil and PE coating be customized?

Yes, the thickness of the foil, MPET, and PE coating can be customized to meet your specific project requirements. - 4. What widths and lengths are available?

The standard widths are 1.0m, 1.2m, and 1.5m, with lengths of 60m, 200m, 300m, and 1000m. Custom sizes are also available upon request. - 5. What are the main benefits of this product?

It offers high tensile strength, excellent corrosion resistance, and simplifies installation by eliminating the need for additional adhesives, making it an environmentally friendly option for insulation lamination.